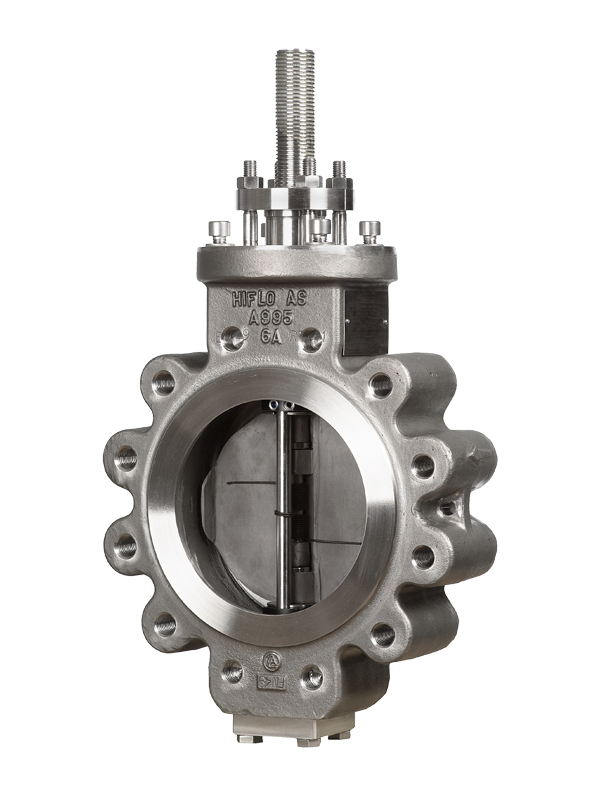

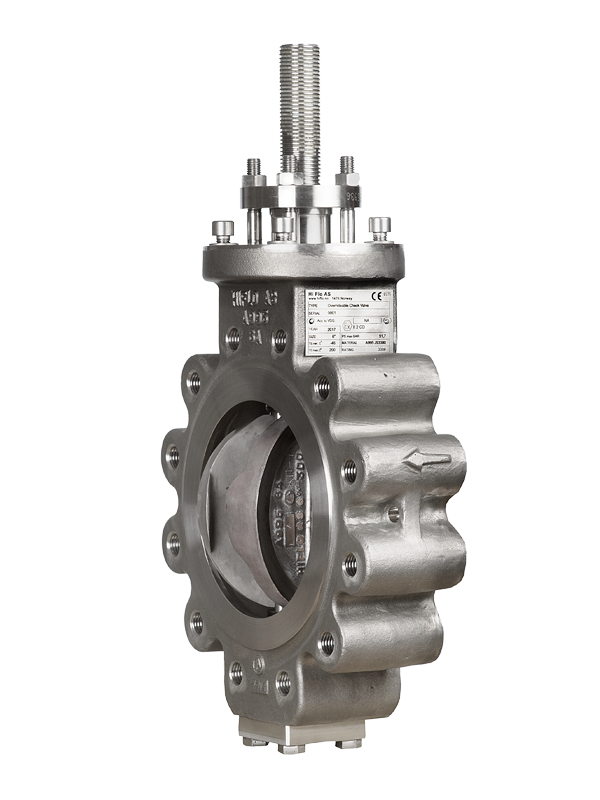

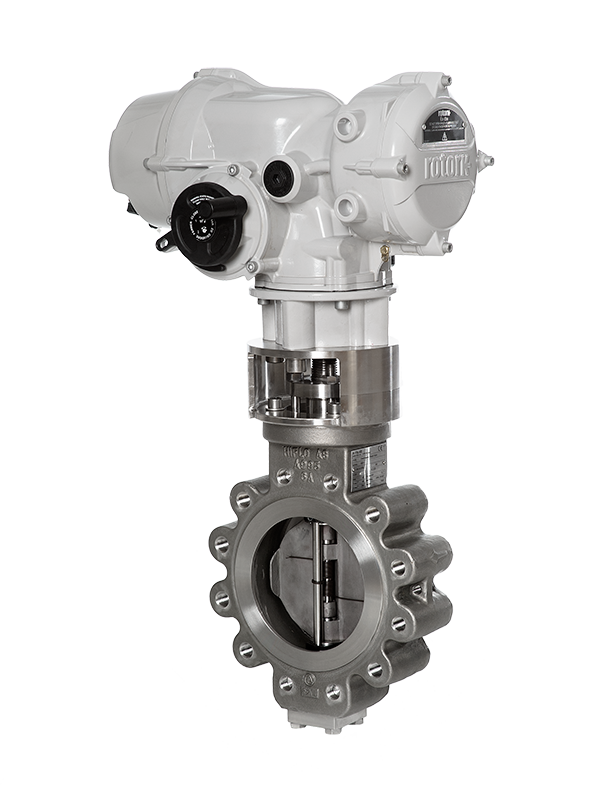

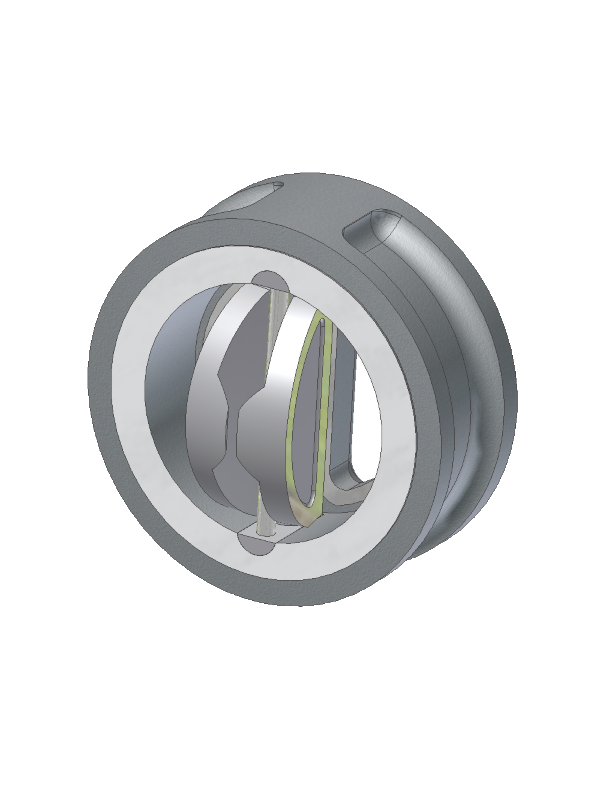

The Dual Plate Check valve has been a popular design in the Oil & Gas- and offshore industry due to the low pressure drop, short reaction time and evenly spread flow through the valve. The patented combination of a rising stem override on a dual plate check valve provided by Hi Flo AS gives you the opportunity to simplify your P&ID by removing drain points, heat tracing, insulation and parallel piping.

This cost efficient design will provide a hammerless process system and is perfect for gas applications. It is also a good choice for vertical applications for water and other fluids if a slightly higher pressure drop can be accepted.

The LoFlo™ control valve is constructed for precise regulation of low flows of media containing particles up to SAE AS4059 class 12B-F.

A special thread constitutes the long flow restriction and the flow is controlled by adjusting the number of threads engaged between a screw and a nut.

A machined groove in the bottom of the male thread constitutes a long flow path which allows for relatively large particles to pass through the valve without clogging. No parts are moving during static operation.

Two spring loaded mechanical scrapers cleans the male thread and the tuned groove when the valve is operated one full cycle.

The valve is perfect for chemical injection applications and automatic sampling stations.

"After six years of late nights and hard work, his patented invention is ready to be presented to the world at the ONS oil and offshore conference in Stavanger. The road from idea to reality has been long for the 41-year-old engineer. Since the thought of an overrideable dual-plate check valve first took shape six years ago Floberg has spent most of his spare time developing the idea on top of his day job as an offshore engineering consultant."

Read the rest of the article from the link below:

sales@hiflo.no

+47 911 77 366